AL 3003 is an alloy with very good corrosion resistance and moderate strength. Excellent weldability, formability, with good mechinability makes 3003 Aluminum Sheet, coil and tread plate is popular and economical choice in Appliance Components. Alloy 3003 can be cold worked to produce tempers with a higher strength but a lower ductility while not heat-treated or used in casting.

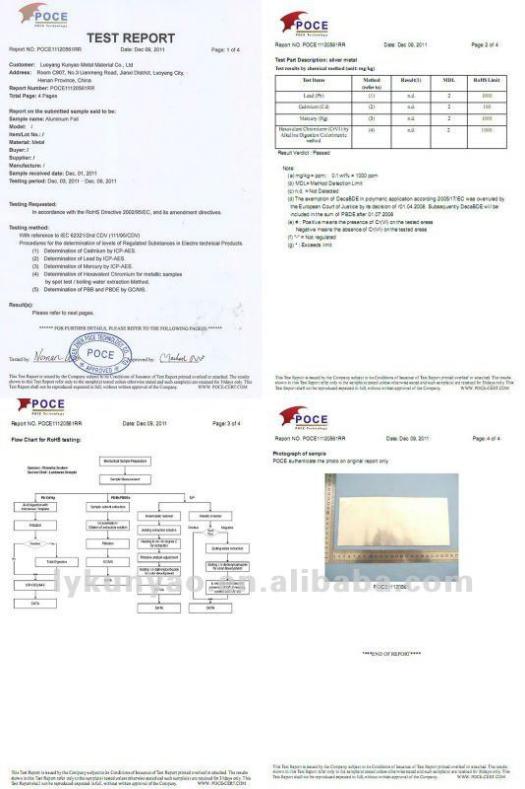

| 3003/4343Aluminum strip/plate for conderser and evaporator etc. | |||||||

| Alloy |

Thickness (mm) |

Temper | Note |

Mpa before Brazing |

Mpa afeter Brazing |

||

|

Tensile Strength |

Yield Strength |

Tensile Strength |

Yield Strength |

||||

| 4343/ 3003/7072 | 0.4-3.0 | O |

Ordinary board material |

95-135 | ≥35 | 110 | 40 |

|

4343/3003 ±0.5% Cu/7072 |

0.4-3.0 | O |

Board material with moderate strength |

120-150 | ≥45 | 135 | 45 |

|

4343/3003 ±0.5% Cu/5005 |

0.4-3.0 | O |

Board material with moderate strength |

120-150 | ≥45 | 135 | 45 |

|

4343/3003 ±0.6% Cu/7072 |

0.4-3.0 | O |

High Strength board material |

130-160 | ≥45 | 140 | 50 |

| 4343/ 3003/7072 | 0.4-3.0 | O |

High Strength board material |

130-160 | ≥45 | 155 | 60 |