Transformers are designed and built with copper or aluminium windings. But transformers using aluminum foil winding have advantage of small size, light weight, good insulation properties, flame retardant, non-polluting, partial discharge, resistant to moisture, smooth and reliable operation, low...

Transformers are designed and built with copper or aluminium windings. But transformers using aluminum foil winding have advantage of small size, light weight, good insulation properties, flame retardant, non-polluting, partial discharge, resistant to moisture, smooth and reliable operation, low noise, and low maintenance cost.

In dry type transformers, aluminium–aluminium windings have been commonly used nowday. Aluminium foil strip can replace copper conductors in distribution transformers. Aluminum foil and sheet in appropriate strip widths and lengths have widely replaced wire in electrical transformers.

Demand for aluminum foil using for oil transformer is new and will be more.

| Specification of Aluminium Strips and Aluminium Foils | ||

| Grade & Temper | Thickness | Width |

| 1050/1060/1070/1350-HO(O) | 0.2-3.0 mm | 20-1350 mm |

| Inner Diameter |

Conductivity Number (% IACS) |

Reisitivity number (Ω·mm² /m) |

| 150/300/400/500 mm | ≥61 | ≤0.027548 |

| Elongation (%) | Tensile strength(Mpa) | Density in 20°C |

| 20 | >60 | 2.7kg/cm3 |

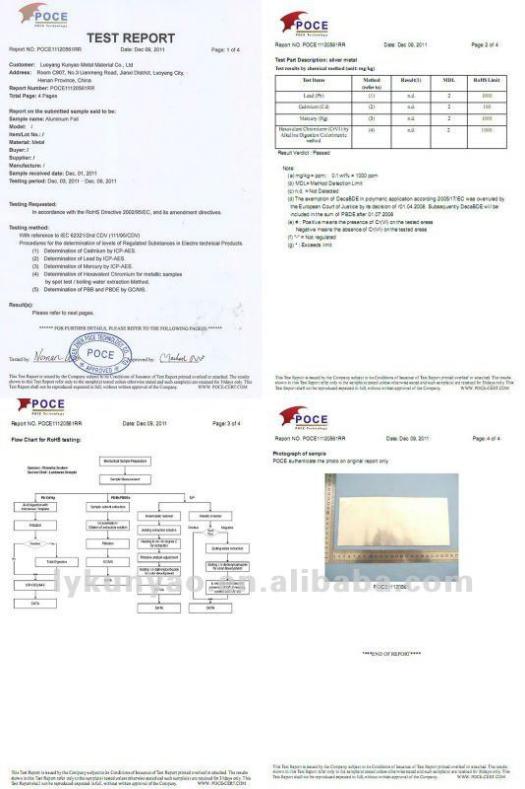

| Note: | Meet RoHS, SGS, REACH, YS/T 713-2009 | |

| Wrought aluminium and aluminium alloy chemical composition | |||||||||

| Grade |

Al(%) MIN |

Si(%) Max |

Fe(%) Max |

Cu(%) Max |

MN(%) Max |

Zn(%) Max |

Mg(%) Max |

Ti(%) Max |

Other elements(%) |

| 1050 | 99.5 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 0.03 |

| 1060 | 99.6 | 0.25 | 0.35 | 0.05 | 0.03 | 0.05 | 0.03 | 0.03 | 0.03 |

| 1070 | 99.7 | 0.25 | 0.04 | 0.03 | 0.04 | 0.04 | 0.03 | 0.03 | |

| 1350 | 99.5 | 0.1 | 0.05 | 0.01 | 0.01 | --- | --- | 0.03 | |

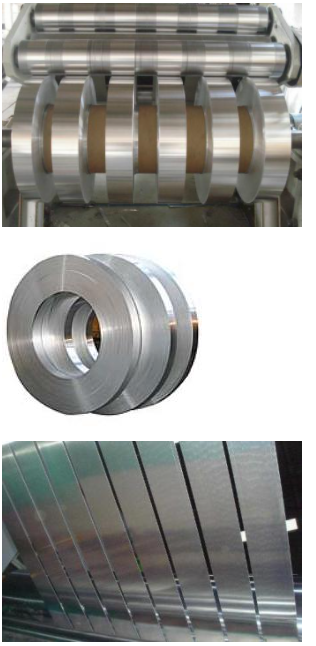

We produce high conductivity roll type electrolytic aluminium strips used to manufacture the windings of electrical transformer, distribution transformer, cast resin transformer.

1. The strip conductor is of high conductivity annealed quality.

2. Slitting is closely controlled to assure strip free of cracks, roughness, scaling, stretch marks.

3. Paper is interleaved between layers of each aluminium coil according to requirement of clients.

4. Each coil is tightly wound.

5. Coil is packed with eye to wall or eye to sky accordingly by sea worthy wooden pallet or box.

6. Foil is free of dents, surface defects, waviness, scale, or any other imperfections which would cause problems in either the winding, performance, or reliability of a quality manufactured dry or wet transformer.

7. The surface and edges of the foil is free of burrs and imperfections. The edges conform to a Round Edge.

8. The strip is shipped in tightly wound rolls with proper edge register.